How to Use Consolidated Fuel for Enhanced Efficiency and Savings?

In today's competitive energy landscape, finding ways to improve efficiency and reduce costs is crucial. Consolidated fuel represents a promising solution for businesses aiming to achieve these goals. Experts in the field, like Dr. Emily Chen, emphasize the importance of this innovation: "Consolidated fuel can transform how industries approach energy use."

The integration of different fuel types into a single, optimized solution can lead to significant savings. This approach enhances efficiency through better energy utilization. However, companies must navigate challenges in implementation. For instance, adapting existing systems to accommodate consolidated fuel may require investments and careful planning.

As organizations explore consolidated fuel, it’s important to reflect on their current practices and be open to change. The transition might reveal inefficiencies in existing operations that need addressing. A thoughtful approach can unlock the full potential of consolidated fuel, paving the way for a more sustainable future.

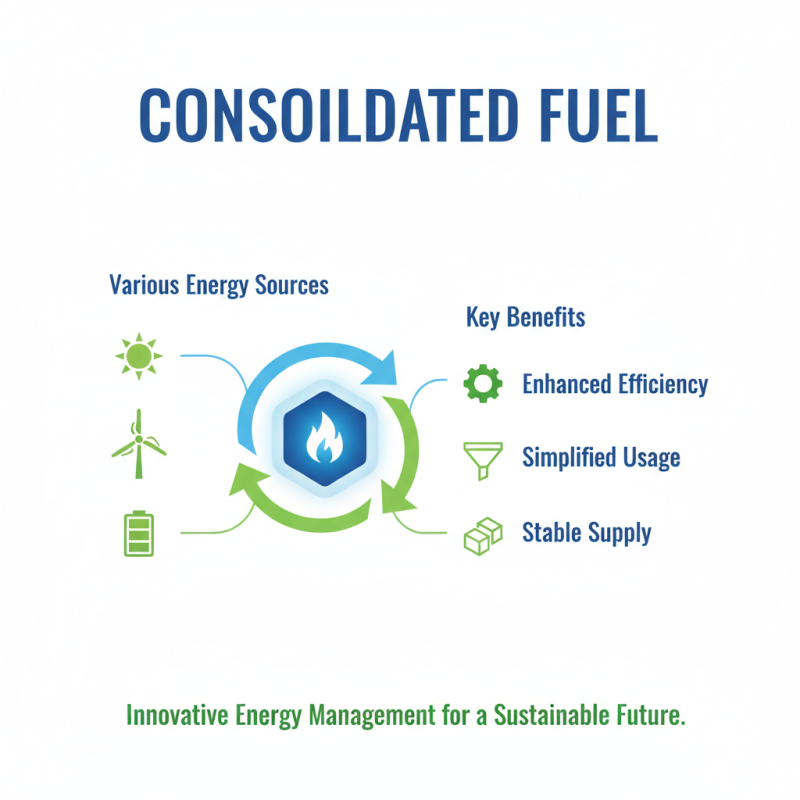

Understanding Consolidated Fuel and Its Benefits

Consolidated fuel is an innovative approach to energy management. It combines various energy sources into one solution. This method can lead to enhanced efficiency. It simplifies fuel usage and reduces waste. By merging fuels, it can provide a more stable supply.

Understanding consolidated fuel helps in recognizing its benefits. It often results in cost savings. For instance, users may consume less fuel overall. This can lower operational costs in the long run. Additionally, consolidated fuel can reduce emissions. This is important for those aiming to be more environmentally friendly.

However, not all applications fit perfectly with this approach. Users might face initial hurdles in integration. It may require adjustments in existing systems. Some might see the change as a hassle. Yet, the long-term benefits often outweigh these challenges. Reflecting on this balance is essential for informed decisions. It's a journey of trial and error, but the potential for enhanced efficiency is undeniable.

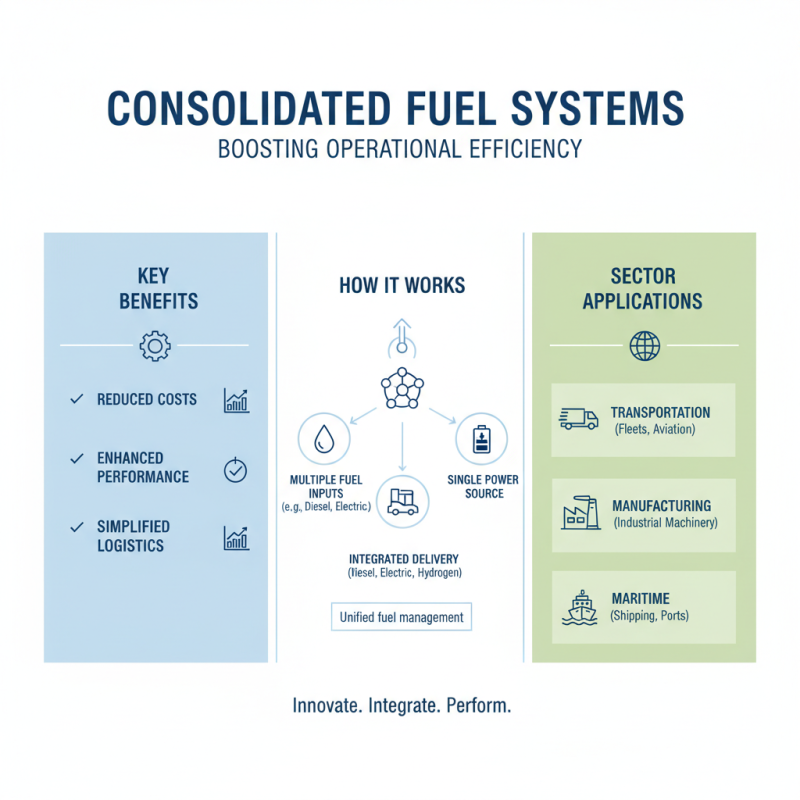

Key Components of Consolidated Fuel Systems

Consolidated fuel systems have become pivotal for improving operational efficiency. These systems integrate various fuel types into a single source. This approach can significantly reduce costs and enhance performance. Such integration can be beneficial in different sectors, from transportation to manufacturing.

Key components of consolidated fuel systems include advanced storage units. These units are designed to minimize space and maximize safety. They often incorporate technology to monitor fuel levels and quality. Another important aspect is the distribution network. A well-designed network ensures quick and consistent fuel delivery, avoiding delays.

Though these systems promise many advantages, some challenges remain. Maintenance can be tricky. Regular inspections are crucial to prevent issues. Additionally, training staff to manage these systems effectively is essential. Without proper knowledge, mistakes are likely, leading to costly errors. Evaluating the system regularly can help identify opportunities for improvement. This critical reflection is necessary for ongoing success.

Steps to Implement Consolidated Fuel Effectively

Implementing consolidated fuel can greatly enhance efficiency and lead to significant savings. To begin, assess your current fuel consumption patterns. Gather data on usage across different equipment and vehicles. This analysis will help you identify inefficiencies.

Tips for assessing fuel usage: Track fuel logs for a month. Compare usage during peak and off-peak periods. Look for inconsistencies. Regular reviews can reveal hidden waste.

Next, choose the right fuel mix. Consider blending options that suit your operations. A well-mixed fuel can improve combustion efficiency. Engage with suppliers to understand blending pros and cons. This step requires careful consideration.

Tips for optimizing your fuel mix: Run small trials with different blends. Monitor performance closely. Adjust based on real-time feedback and results. Don't be afraid to experiment and learn from failures. Each attempt will teach valuable lessons.

Measuring Efficiency Gains from Consolidated Fuel Usage

Consolidated fuel usage can lead to notable efficiency gains. Recent studies indicate that optimizing fuel sources can reduce operational costs by up to 20%. This shift enhances energy efficiency and minimizes waste. By consolidating fuel types, businesses can streamline their supply chains. This often results in increased reliability in fuel availability and reduced downtime.

Measuring the efficiency gains from consolidated fuel can be complex. The key is tracking fuel consumption against performance metrics. For instance, a report showed that companies adopting consolidated fuel strategies saved an average of 15% in energy costs annually. The efficiency gains can also lead to improved machinery performance, extending equipment life. However, not every organization sees immediate benefits. The transition phase requires careful monitoring to identify areas needing further refinement.

Data collection is crucial in understanding the benefits of consolidated fuel. Tracking usage patterns and maintenance records can provide insights into efficiency trends. Some companies report challenges in achieving desired outcomes. It is essential to regularly evaluate the impact and adjust strategies accordingly. Through proactive management, businesses can maximize the advantages of consolidated fuel.

Tips for Maximizing Savings with Consolidated Fuel Solutions

Consolidated fuel solutions can significantly enhance efficiency in energy usage. These solutions simplify the fuel procurement process. Streamlining fuel acquisition can save time and reduce costs. However, not all options are equal; careful selection is key.

To maximize savings, analyze your current fuel consumption patterns. Identify peak usage times and low-demand periods. This knowledge helps in negotiating better contracts. Regularly review fuel prices to take advantage of market fluctuations. Even small changes in purchasing habits can lead to significant savings.

Monitoring your fuel usage is vital. Track overall efficiency and waste. This might reveal unexpected problems. Sometimes, the solution is not just about changing suppliers but adjusting usage habits as well. Engage your team in discussions about efficiency, as they may have valuable insights. Over time, these small adjustments can lead to substantial cost reductions.

Related Posts

-

Unlocking the Future of Energy: How Consolidated Fuel is Revolutionizing the Fuel Industry

-

Understanding the Evolution of Aircraft Service: From Maintenance to Passenger Experience

-

Top Kit Aircraft for Enthusiasts and Builders in 2026?

-

What is Fuel System Aviation and How Does It Impact Flight Safety

-

10 Essential Tips for Understanding Aircraft Systems Effectively

-

Top 10 Fuel System Aviation Innovations You Need to Know About