Unlocking Efficiency: A Deep Dive into Fuel Flow Dynamics in Modern Engines

In the quest for enhanced performance and sustainability, understanding the intricacies of fuel flow dynamics in modern engines is essential. Fuel flow, the pathway through which fuel travels from the tank to the combustion chamber, plays a critical role in determining an engine's efficiency and power output. As technological advancements continue to reshape the automotive landscape, a comprehensive exploration of how fuel flow interacts with combustion processes, air intake, and fuel injection systems reveals significant insights. This deep dive into fuel flow dynamics not only uncovers the mechanisms that govern engine performance but also highlights the potential for innovative solutions aimed at optimizing energy use, reducing emissions, and improving overall operational reliability. As we unlock the secrets of fuel flow, we pave the way for a new era of engineering excellence in the development of cleaner and more efficient engines.

Understanding Fuel Flow Mechanics in Engine Design

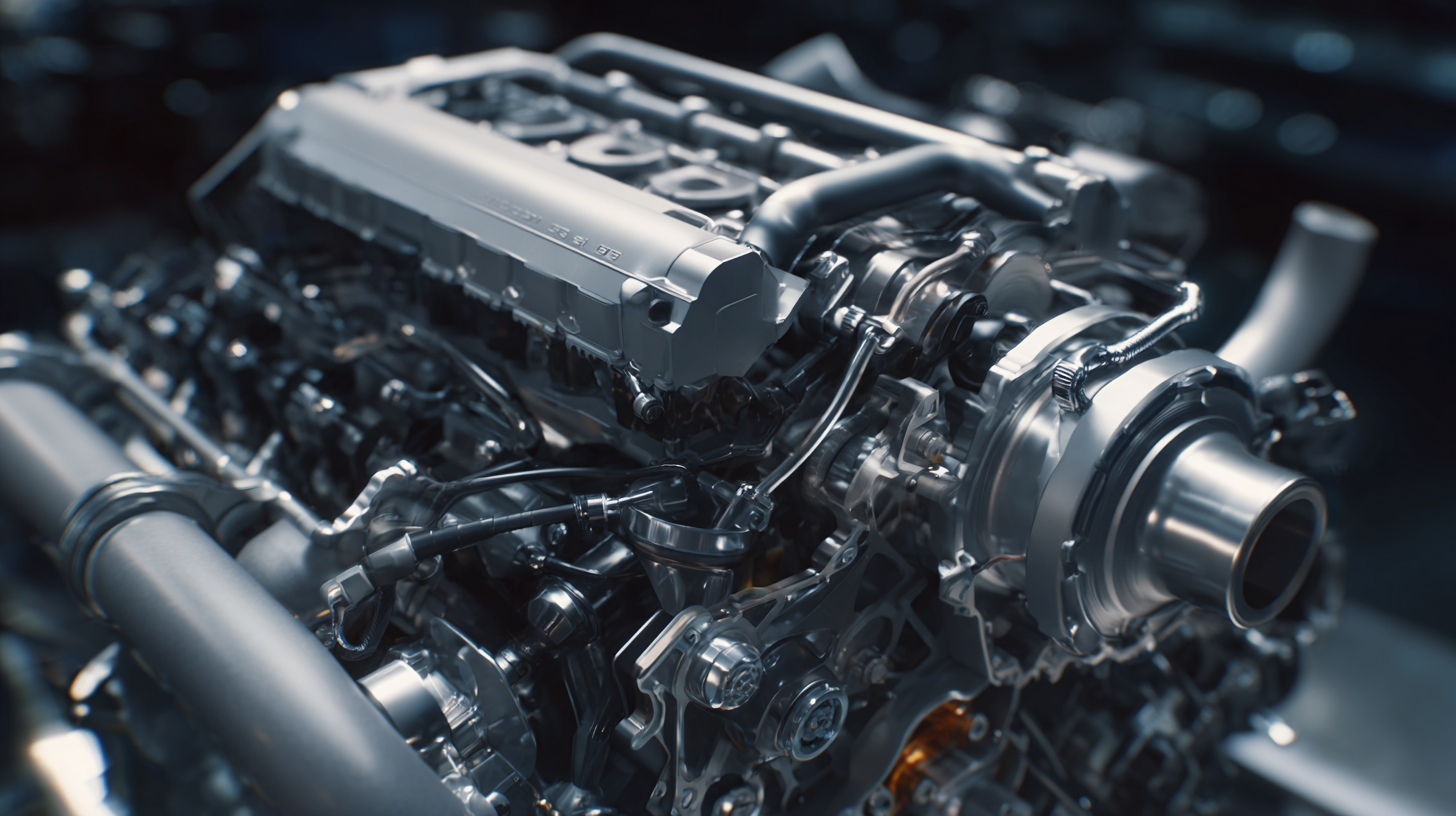

Understanding fuel flow mechanics is crucial in modern engine design, as it directly influences performance, efficiency, and emissions. Fuel flow dynamics involve a series of complex processes where fuel is delivered to the combustion chamber in an optimized manner. Designers employ advanced fuel injection systems to ensure precise timing and atomization of the fuel, which enhances combustion efficiency. This precision minimizes fuel wastage and maximizes power output, allowing engines to meet stringent environmental regulations while maintaining performance standards.

Furthermore, the layout and materials used in fuel delivery systems play a significant role in overall efficiency. For instance, the design of fuel lines and filters must minimize resistance and potential contaminants while ensuring a consistent flow. Innovative technologies like variable displacement pumps and electronic control units are increasingly integrated into engine designs to better manage fuel flow under varying operational conditions. As engineers continue to prioritize these elements, a deeper understanding of fuel flow mechanics will pave the way for even more advanced and sustainable engine solutions.

Key Factors Influencing Fuel Efficiency in Modern Powertrains

In modern powertrains, several key factors significantly influence fuel efficiency, which is a critical metric for both environmental sustainability and economic performance. Engine design innovations, such as direct fuel injection and turbocharging, have demonstrated marked improvements in efficiency. According to a report by the International Council on Clean Transportation (ICCT), vehicles equipped with turbocharged engines can achieve up to 20% better fuel economy than their naturally aspirated counterparts. This is largely due to the ability of turbochargers to extract more energy from exhaust gases, thereby enhancing the engine's thermal efficiency.

Moreover, vehicle weight plays a pivotal role in fuel consumption. As per data from the U.S. Department of Energy, reducing a vehicle's weight by 10% can improve fuel economy by approximately 6-8%. Manufacturers increasingly utilize lightweight materials, such as advanced composites and high-strength steel, in a bid to minimize weight without compromising safety or performance.

Additionally, the integration of hybrid and electric powertrains further contributes to fuel efficiency. The U.S. Environmental Protection Agency reported that hybrid vehicles can achieve fuel economy ratings exceeding 50 miles per gallon, underscoring the effectiveness of innovative powertrain technologies in unlocking greater efficiency in modern engines.

Advanced Technologies Enhancing Fuel Flow Optimization

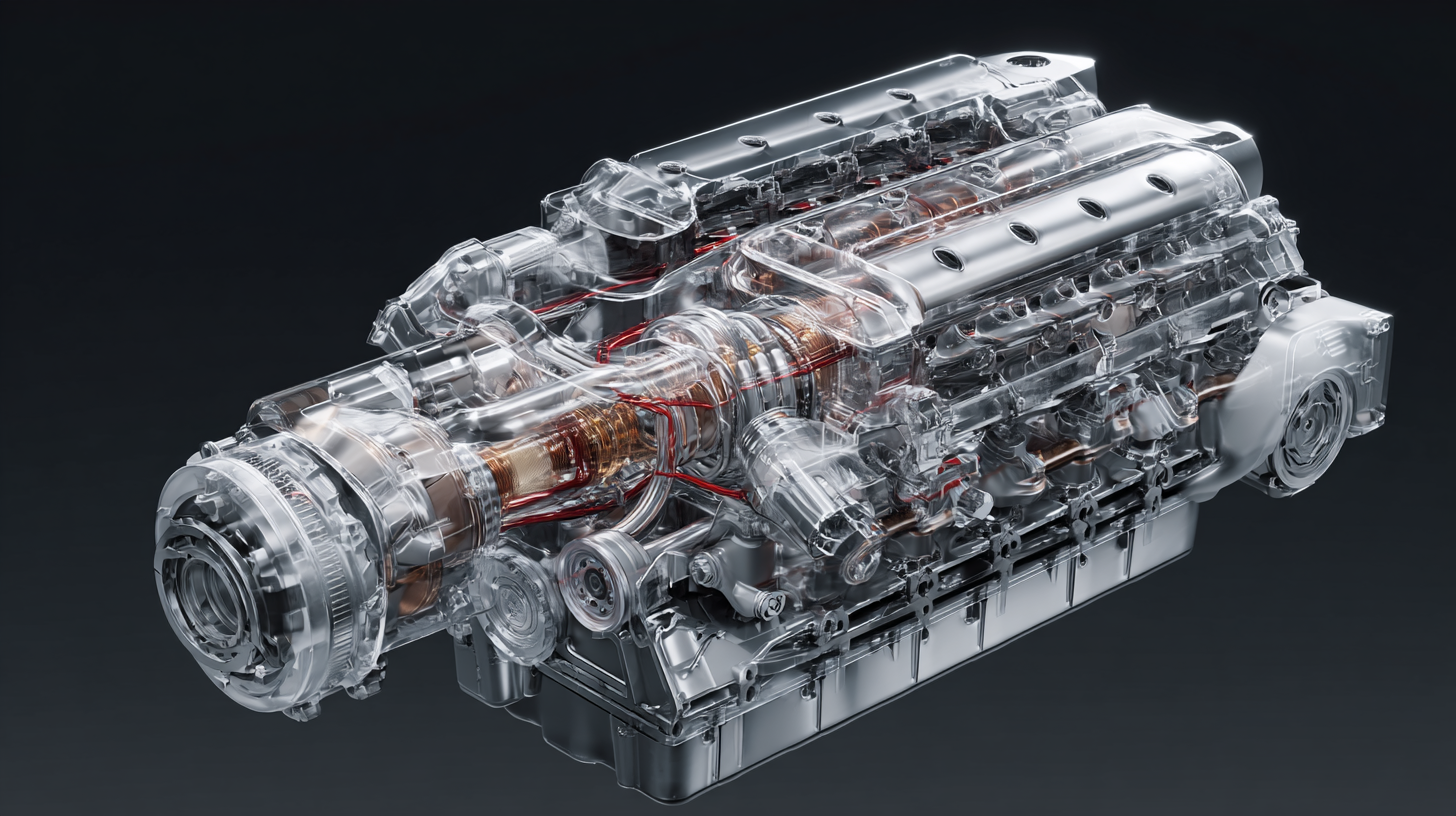

Modern engines are experiencing a significant transformation due to advanced technologies that enhance fuel flow optimization. Innovations such as variable valve timing (VVT) and direct fuel injection are pivotal in maximizing the efficiency of fuel consumption. According to the International Council on Clean Transportation (ICCT), these technologies can boost fuel efficiency by as much as 15%, a crucial improvement in the face of rising fuel prices and stricter emissions regulations.

Integrating electronic control units (ECUs) with advanced algorithms is another trend that refines fuel flow dynamics. By constantly monitoring engine performance in real time, these systems can adjust fuel delivery based on demand, thus minimizing waste. A report from the Society of Automotive Engineers (SAE) indicates that the implementation of such smart systems can lead to a reduction in carbon emissions by up to 20%, aligning with global sustainability goals.

**Tips:** To further enhance fuel flow efficiency, consider regular maintenance of engine components such as filters and injectors. Ensuring these parts are clean and functioning properly can prevent fuel flow obstructions and improve overall engine performance. Additionally, adopting eco-friendly driving habits, like smooth acceleration and maintaining optimal speeds, can significantly reduce fuel consumption.

Fuel Flow Optimization in Modern Engines

This chart illustrates the fuel efficiency of various modern engine technologies, showcasing the evolution from traditional carbureted systems to advanced turbocharged direct injection systems, emphasizing the significant improvements in fuel flow optimization.

The Role of Aerodynamics in Fuel Delivery Systems

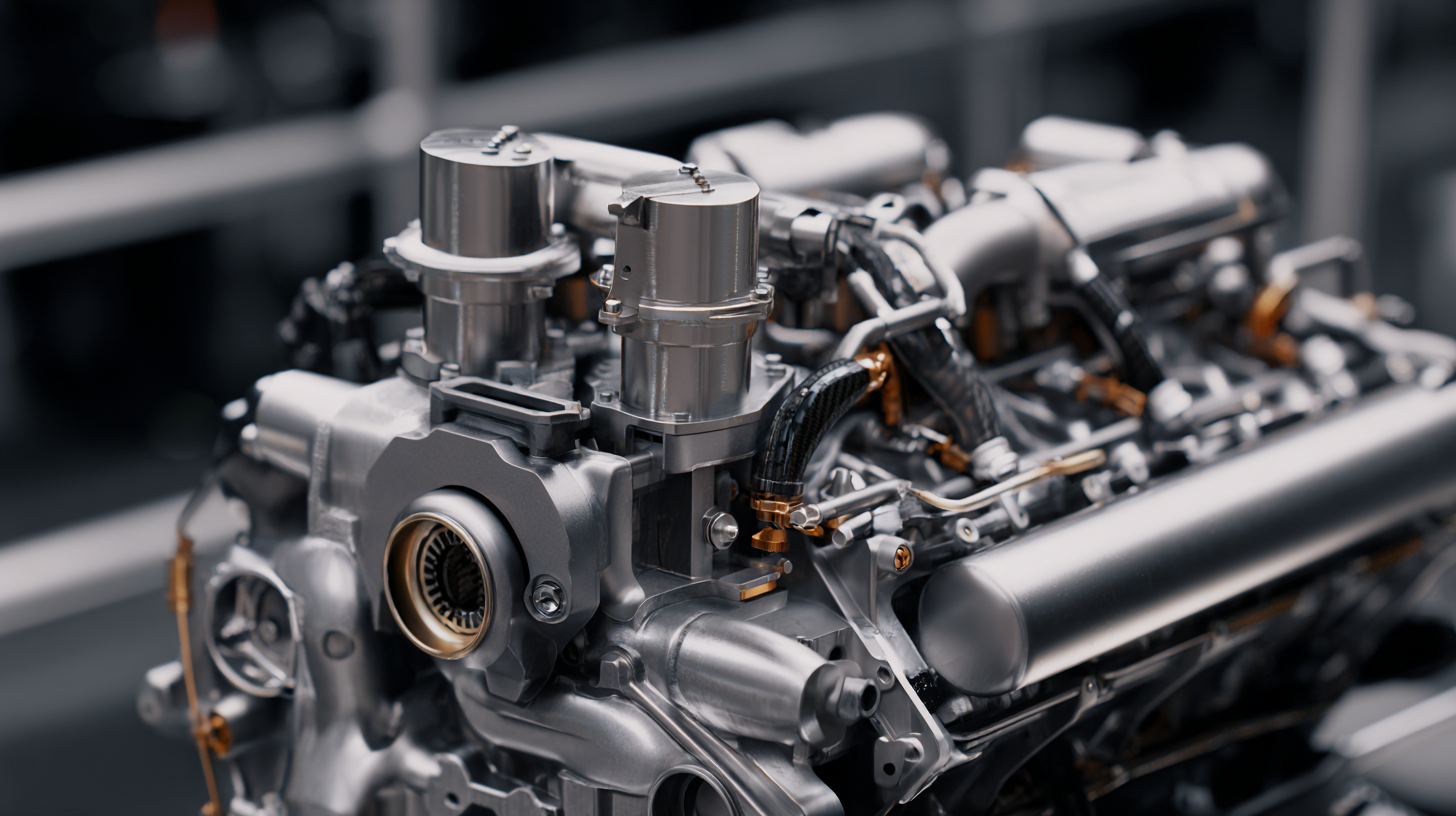

In modern engines, the intricacies of fuel delivery systems are significantly influenced by aerodynamic principles. Understanding how air flows within combustion chambers can lead to remarkable improvements in fuel efficiency and engine performance.

Aerodynamics plays a crucial role in shaping the design of intake manifolds and fuel injectors, ensuring optimal fuel atomization and distribution. By facilitating smoother airflow, engineers can create conditions that enhance fuel combustion, leading to increased power output and decreased emissions.

Aerodynamics plays a crucial role in shaping the design of intake manifolds and fuel injectors, ensuring optimal fuel atomization and distribution. By facilitating smoother airflow, engineers can create conditions that enhance fuel combustion, leading to increased power output and decreased emissions.

Tips: When considering improvements to your engine's performance, pay attention to the shape and layout of your intake system. A streamlined design can reduce turbulence, ultimately promoting better fuel flow dynamics.

Furthermore, harnessing aerodynamic insights enables engineers to innovate fuel injection strategies. By adjusting the angle and timing of fuel delivery, they can synchronize the injection process with the engine's intake stroke. This precise coordination ensures a homogeneous fuel-air mixture, resulting in more efficient combustion. As a result, vehicles can achieve higher mileage and lower carbon footprints without sacrificing power.

Tips: Regularly maintain your fuel delivery system to ensure that all components are functioning optimally. A clean fuel filter and well-calibrated injectors can significantly enhance overall engine efficiency.

Tips for Maintaining Optimal Fuel Flow in Automotive Engines

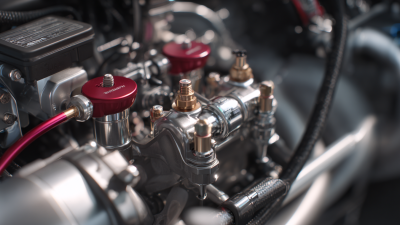

Maintaining optimal fuel flow in automotive engines is crucial for maximizing performance and efficiency. One of the key aspects is ensuring that the fuel system is clean and well-maintained. Regularly replacing the fuel filter can prevent debris from clogging the fuel lines, which can disrupt fuel flow and reduce engine performance. Additionally, using high-quality fuel can minimize deposits in the system, contributing to smoother combustion and improved overall efficiency.

Another important tip is to monitor the fuel pressure. An adequate fuel pressure ensures that the engine receives the right amount of fuel at all times. If the pressure is too low, it may lead to fuel starvation, which can cause stalling or poor acceleration. Investing in a pressure gauge can help you keep track of these readings and identify any potential issues before they escalate.

Lastly, consider the role of the fuel injectors. Regularly inspecting and cleaning fuel injectors can help maintain optimal spray patterns, ensuring better fuel atomization and combustion efficiency. If you notice rough idling or a drop in fuel efficiency, it might be time to service or replace the injectors to restore peak performance.

Unlocking Efficiency: A Deep Dive into Fuel Flow Dynamics in Modern Engines

| Engine Type | Fuel Type | Optimal Flow Rate (L/min) | Common Issues | Maintenance Tips |

|---|---|---|---|---|

| Petrol Engine | Unleaded Petrol | 2.5 | Clogged Fuel Filter | Replace fuel filter every 12,000 miles. |

| Diesel Engine | Diesel | 3.0 | Injector Failure | Check injectors annually for wear. |

| Hybrid Engine | Gasoline & Electric | 1.8 | Battery Efficiency | Regularly check battery health and connections. |

| Turbocharged Engine | Premium Petrol | 2.8 | Boost Pressure Issues | Monitor boost levels and replace worn components. |

Related Posts

-

Innovative Aviation Kits Showcase Opportunities at the 2025 China Import and Export Fair

-

Revolutionizing Aviation: The Future of Fuel Injection Systems in Aircraft Design

-

Exploring the Future of Fuel Injection Aircraft: Innovations and Advancements in Aviation Technology

-

Fuel Injection Aircraft Innovations Showcased at the 138th Canton Fair 2025

-

5 Best Solutions for Exceptional Aircraft Service Efficiency

-

Exploring the Future of Fuel System Aviation at the 138th Canton Fair 2025