How to Optimize Fuel Injection System in Aviation for Better Performance?

The fuel injection system in aviation plays a critical role in aircraft performance. Ensuring optimal operation of this system can vastly improve efficiency, increase power output, and enhance overall reliability. A well-tuned fuel injection system aviation can lead to better fuel economy. This, in turn, reduces operational costs and lowers emissions.

However, many systems are not operating at peak potential. Issues such as poor maintenance, improper calibration, and outdated technology contribute to performance deficits. Identifying these shortcomings is essential for enhancing overall system effectiveness. A simple evaluation might reveal unexpected discrepancies. Regular inspections and updates can address common issues and improve system functions.

Innovation in fuel injection technology continues to evolve, but implementation can be challenging. The aviation industry must adapt to these advances while reflecting on past practices. Continuous improvement is vital for achieving better aircraft performance. Embracing change will create a more efficient and sustainable aviation environment.

Understanding the Basics of Fuel Injection Systems in Aviation

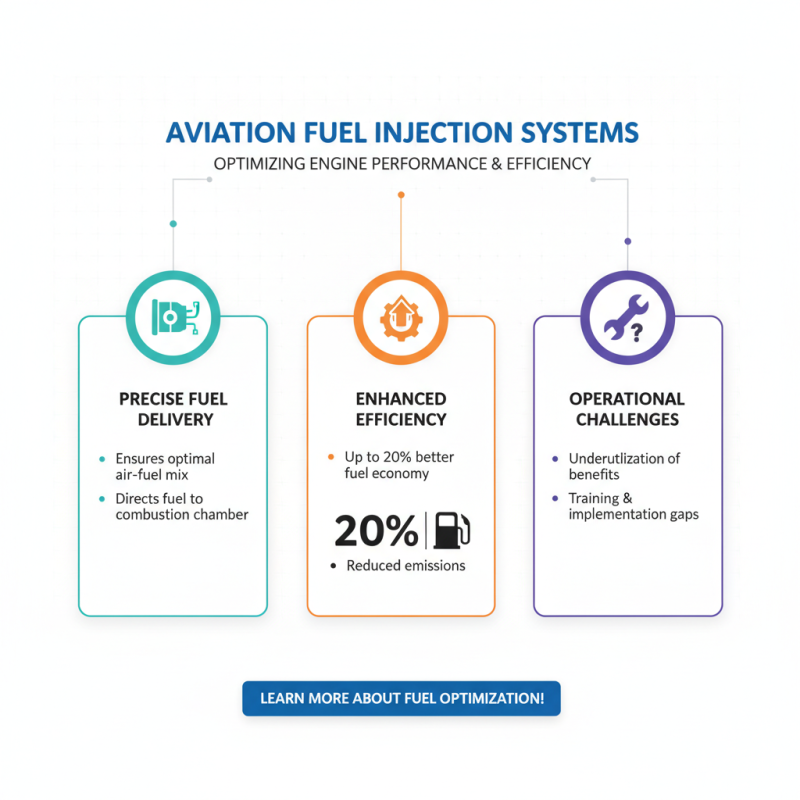

Fuel injection systems in aviation play a crucial role in engine performance. These systems ensure the precise delivery of fuel to the combustion chamber, optimizing the air-fuel mixture. In recent studies, it has been noted that precise fuel injection can enhance engine efficiency by up to 20%. Such improvements lead to better fuel economy and reduced emissions. However, many aviation operators still struggle to fully utilize these advantages.

Understanding the components of fuel injection systems is essential. These systems include fuel pumps, injectors, and control units. Each part must work in harmony to achieve optimal performance. Research indicates that improper calibration can lead to inefficiencies. For example, a study revealed that a mere 1% error in fuel flow can result in a 5% drop in overall engine performance. This emphasizes the need for regular maintenance and calibration checks.

Challenges exist in the effective implementation of fuel injection systems. Many aircraft still operate with outdated technology. This can hinder performance and increase operational costs. Emerging technologies such as direct fuel injection offer promising solutions. Yet, the transition can be slow due to financial and logistical constraints. Addressing these issues is vital for enhancing the overall performance of aviation fuel injection systems.

Key Components of Fuel Injection Systems and Their Functions

The fuel injection system in aviation plays a crucial role in engine performance. Key components include fuel pumps, injectors, and control units. Fuel pumps ensure a constant flow of fuel at the required pressure. Reports show that a properly functioning fuel pump can improve engine efficiency by up to 20%. However, if the pump is faulty, it can lead to engine failure.

Fuel injectors atomize the fuel for better combustion. Their design directly affects performance and emissions. Studies indicate that injector issues can reduce power output by nearly 15%. Regular maintenance is vital, yet many operators overlook this aspect. Some even depend on outdated systems, risking operational efficiency.

Control units manage the fuel-to-air ratio. An imbalance can lead to excessive fuel use and suboptimal engine performance. An ideal ratio typically maximizes thrust while minimizing fuel consumption. However, achieving this balance can be tricky. Many systems require recalibration, which is often neglected. This oversight can hinder overall effectiveness and cost savings.

Techniques for Enhancing Fuel Efficiency and Performance

Enhancing fuel efficiency in aviation is a critical area for research and development. Reports indicate that inefficient fuel injection systems can waste up to 15% of fuel. This wastage not only affects economic performance but also increases emissions. Optimizing these systems can significantly improve overall aircraft performance and operational costs.

One effective technique involves fine-tuning injector timing and spray patterns. Studies show that precise control of fuel atomization can lead to better combustion efficiency. . For instance, well-designed injector nozzles can improve fuel delivery accuracy. This adjustment allows for a more complete combustion cycle, which translates to higher thrust and lower fuel consumption. Additionally, regular maintenance of fuel filters ensures consistent injector performance.

However, challenges remain in achieving the ideal balance between power and efficiency. Often, modifications can strain engine components, leading to increased wear. These trade-offs require careful consideration and extensive testing. Emerging technologies, like digital fuel management systems, promise improvements. Yet, integrating these solutions introduces complexities in existing frameworks. The overall goal is clear: maximize efficiency while ensuring reliability. Continuous assessment of these systems is necessary as the aviation landscape evolves.

Common Issues and Troubleshooting Strategies for Fuel Injection Systems

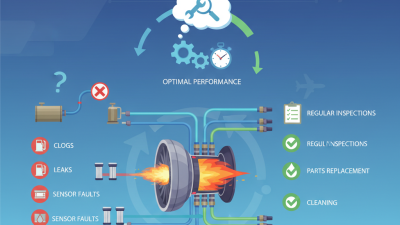

Fuel injection systems in aviation are critical for engine performance and efficiency. However, these systems often face common issues that can hinder functionality. Clogging filters and fuel lines is a frequent problem. It can cause decreased fuel flow and lead to engine performance dips. According to a recent industry report, nearly 25% of general aviation engine failures are linked to fuel system issues. Regular maintenance and thorough inspections are vital to address these problems before they escalate.

Troubleshooting fuel injection systems is essential for optimal performance. Pilots and technicians should be vigilant for signs of irregular engine behavior. Symptoms like rough idling or sudden power loss often indicate fuel delivery issues. A common strategy is to use diagnostic tools to monitor fuel pressure and injector output. Reports show that addressing these variables can improve efficiency by up to 15%. A holistic approach to maintenance, including routine checks on filters and injectors, significantly reduces the chance of unexpected failures. Oversights in preventive measures can severely impact performance and safety.

How to Optimize Fuel Injection System in Aviation for Better Performance?

| Issue | Description | Troubleshooting Strategy | Common Symptoms |

|---|---|---|---|

| Clogged Fuel Injectors | Fuel injectors can become clogged with deposits, impacting flow and performance. | Perform a thorough cleaning using injector cleaner or ultrasonic cleaning. | Decreased engine performance, idle roughness, or poor fuel economy. |

| Incorrect Fuel Pressure | Fuel pressure may be too high or too low, affecting combustion and efficiency. | Check and adjust the fuel pressure regulator; replace if faulty. | Engine stalling, hesitation during acceleration, or backfiring. |

| Faulty Sensors | Sensors like the mass airflow or oxygen sensor may send incorrect data. | Test sensors with a multimeter; replace faulty sensors. | Check engine light, poor fuel economy, or inconsistent engine performance. |

| Air Leaks | Leaking air affects the air-fuel mixture, leading to suboptimal combustion. | Inspect intake manifolds and hoses for leaks; use a smoke test if necessary. | Rough idle, engine misfires, and decreased acceleration. |

| Injector Timing Issues | Improper injector timing can result in poor fuel atomization. | Check timing settings and adjust or reflash the ECU if needed. | Loss of power, rough running, and high emissions. |

Future Trends in Aviation Fuel Injection Technology and Optimization

As the aviation industry evolves, the focus on fuel injection systems intensifies. Future trends point to integrating data analytics and AI for optimization. Reports from the International Society of Air Safety Investigators indicate that optimized fuel systems can reduce fuel consumption by up to 15%. Such reductions translate directly into lower operational costs.

Innovative materials are also emerging. Lightweight and high-thermal-resistant materials improve not only efficiency but also reliability. For instance, researchers observe potential increases in performance by utilizing composites. However, these advancements require careful consideration. The cost of development and certification remains high. Many companies hesitate to invest in new technologies due to uncertain returns.

Redundancy in systems is another area for reflection. Implementing multiple fuel injection strategies could enhance safety but complicate maintenance. Industry experts warn that over-reliance on technology may lead to complacency. Balancing cutting-edge solutions with traditional methods might be vital for sustainable growth. As the sector faces increasing demands, finding this equilibrium becomes crucial.

Related Posts

-

How to Troubleshoot and Maintain Fuel Injection Systems in Aircraft

-

Revolutionizing Aviation with Advanced Fuel Injection Systems Enhancing Efficiency and Performance

-

How to Optimize Fuel Injection System for Aircraft Performance

-

Building Your Dreams: A Comprehensive Guide to DIY Kit Aircraft for Aviation Enthusiasts

-

How to Optimize Fuel Injection in Aviation for Better Performance and Efficiency

-

10 Essential Tips for Managing Aircraft Fuel Efficiency and Cost