2026 How to Optimize Consolidated Fuel Usage for Energy Efficiency?

The pursuit of energy efficiency is more crucial than ever. In the consolidated fuel industry, experts emphasize optimization strategies. John Smith, a leading voice in this sector, once stated, "Efficient fuel usage is not just a trend; it’s a necessity." This quote underscores the pressing need for innovation in fuel consumption.

Consolidated fuel combines various energy sources to enhance performance. Companies face challenges in balancing cost and efficiency. Real-world applications often reveal gaps in strategy. Many firms struggle to implement effective solutions in their operations. This inconsistency prompts reflection on current practices. How can the industry embrace change?

In 2026, the focus will be on optimizing consolidated fuel usage. By leveraging technology and best practices, sectors can improve their energy profiles. The path to efficiency may not be straightforward. It requires ongoing assessment and adaptation. Only through collective effort can tangible progress be achieved in this vital area.

Understanding Consolidated Fuel Usage and Its Importance

Consolidated fuel usage refers to the collective consumption of multiple fuel sources in various operations. Understanding its importance is vital for improving energy efficiency. Optimizing this usage can help reduce waste and cut costs. Companies often overlook the impact of fuel consolidation due to a lack of awareness. This can lead to inefficiencies in resource allocation and higher operational costs.

Energy efficiency is not just a buzzword; it has tangible benefits. For instance, by analyzing fuel consumption data, organizations can identify patterns. They may find that certain processes consume more fuel than necessary. This realization can trigger changes in operations. Simple adjustments can lead to significant savings. However, many companies hesitate to make drastic changes. Fear of disruption can hold them back.

Moreover, the environmental implications of fuel usage are crucial. Excessive fuel consumption contributes to pollution and climate change. Companies need to reflect on their role in these issues. It is essential to strike a balance between operational needs and sustainable practices. This reflective approach can lead to innovative solutions that enhance efficiency while protecting the planet. Adopting consolidated fuel strategies is a step toward a more responsible future.

Analyzing Current Fuel Consumption Patterns for Optimization

To improve energy efficiency in fuel consumption, understanding current patterns is crucial. Many facilities overlook small inefficiencies. These can accumulate and lead to significant waste. For instance, a factory might run machinery longer than needed, wasting fuel. Analyzing usage data can spotlight such missteps. Regular audits can reveal when equipment operates at peak efficiency.

Tips for optimizing fuel usage: Track daily fuel consumption. Identify peak usage periods. Assess if operations align with fuel consumption patterns. Explore alternative methods and technologies. Often, small changes yield big results. Train employees on efficient fuel practices. A well-informed team can spot issues faster.

Maintaining transparency in fuel tracking encourages accountability. Sometimes, outdated technologies are still in use. This can hamper efficiency. It’s important to question whether existing solutions still serve their purpose. Reviewing current systems regularly allows for informed decisions. Consider all options, from maintenance to replacement. Patterns might reveal more than expected.

2026 How to Optimize Consolidated Fuel Usage for Energy Efficiency?

| Fuel Type | Monthly Consumption (liters) | Average Cost per Liter ($) | Total Monthly Cost ($) | Energy Efficiency Rating |

|---|---|---|---|---|

| Diesel | 5000 | 3.50 | 17500 | B |

| Gasoline | 3000 | 3.00 | 9000 | C |

| Natural Gas | 8000 | 1.80 | 14400 | A |

| Biofuel | 2000 | 2.50 | 5000 | A+ |

| Electricity | 25000 | 0.15 | 3750 | A++ |

Implementing Technology Solutions for Enhanced Energy Efficiency

In today's world, optimizing fuel usage is essential for enhancing energy efficiency. Implementing technology solutions can drive significant improvements. For instance, smart meters provide real-time data on energy consumption. This allows businesses to identify waste and adjust their usage accordingly. However, the initial cost of such technology can be a barrier.

Another effective approach is using data analytics. Analyzing consumption patterns helps in predicting energy needs more accurately. This can reduce excess fuel usage in operations. Yet, organizations must invest time in understanding these patterns. Many overlook the importance of employee training on these new systems.

Adopting renewable energy sources is also a step toward efficiency. Solar panels and wind turbines can provide alternative power. Although the transition requires effort, the long-term benefits are substantial. Still, some may find it challenging to shift from traditional energy sources. Thoughtful integration of these technologies can lead to better fuel optimization, but there is always room for improvement and reflection.

2026 Energy Efficiency Optimization: Fuel Usage Analysis

Strategies for Reducing Fuel Waste in Operations

Fuel waste can significantly impact operations. Many organizations overlook simple adjustments that lead to better efficiency. Regular maintenance of machinery is essential. Broken equipment often consumes more fuel. Workers should conduct inspections to identify potential issues. This not only enhances performance but also minimizes waste.

Training staff is another pivotal strategy. When employees understand fuel-efficient practices, they contribute positively. It’s crucial to encourage dialogue about fuel usage. Employees often have insights into everyday operations that management might miss. Creating a feedback loop can reveal overlooked areas for improvement.

Implementing technology can also help. Monitoring systems can track fuel consumption closely. However, these systems must be user-friendly to ensure compliance. Yet, it is easy to become overly reliant on technology. Balancing tech usage with human observation is vital. Sometimes, individuals can notice inefficiencies that data alone cannot reveal. Identifying these discrepancies requires effort and reflection from everyone involved.

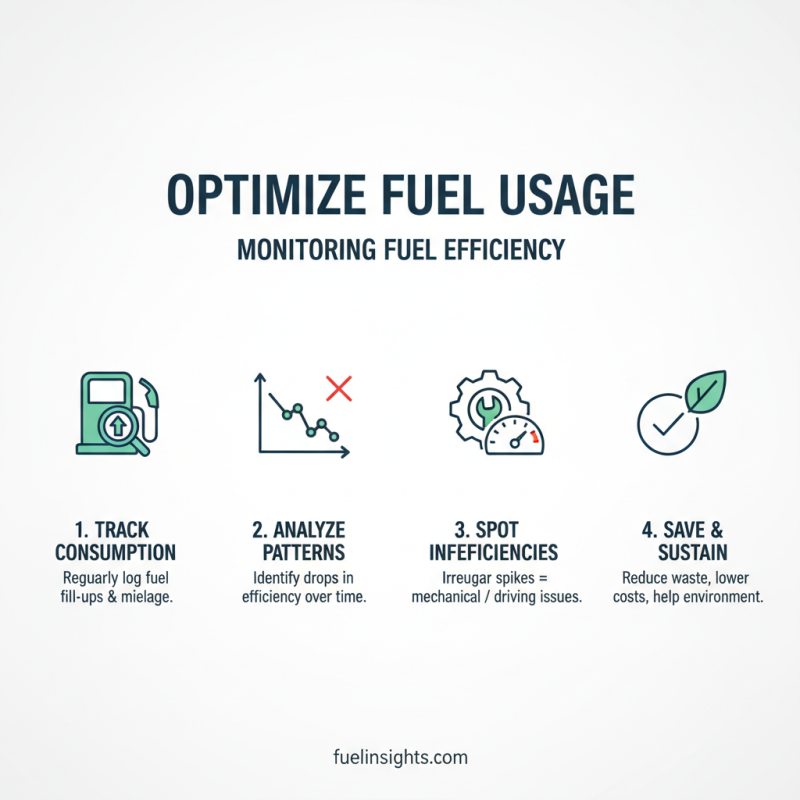

Monitoring and Evaluating Fuel Efficiency Improvements

Monitoring fuel efficiency is crucial for optimizing consolidated fuel usage. Regular assessments can identify where fuel is wasted. This involves tracking consumption patterns over time. Analyzing these patterns helps to spotlight inefficiencies. For instance, irregular fuel spikes may indicate mechanical issues or poor driving habits.

Evaluating improvements in fuel efficiency can be more complex. Simple metrics, like miles per gallon, often miss underlying problems. It’s essential to consider vehicle load and travel conditions. Additionally, individual behaviors impact overall efficiency. Planning routes and reducing idling times can yield unexpected gains. Simple changes sometimes lead to significant results.

Yet, challenges persist. Data collection can be inconsistent, leading to flawed analysis. Employees may resist changes to their routines, even positive ones. Finding the right motivation to adapt is key. Awareness campaigns can help, but they require time to sink in. Small wins can gradually shift mindsets. Ultimately, continuous monitoring and evaluation are essential for sustainable improvements.

Related Posts

-

How to Use Consolidated Fuel for Enhanced Efficiency and Savings?

-

Exploring the Future of Fuel System Aviation at the 138th Canton Fair 2025

-

What is General Aviation and Why is it Important for the Aviation Industry

-

5 Best Solutions for Exceptional Aircraft Service Efficiency

-

Fuel Injection Aircraft Innovations Showcased at the 138th Canton Fair 2025

-

10 Essential Tips for Understanding Aviation Fuel Systems