What is a Fuel Flow Divider and How Does It Work in Aircraft Engines?

In the realm of aviation, maintaining optimal fuel efficiency and engine performance is paramount for the safe operation of aircraft. One crucial component that plays a significant role in achieving this efficiency is the fuel flow divider. This sophisticated device is integral to the fuel distribution system in aircraft engines, ensuring that the right amount of fuel reaches each cylinder for combustion. Understanding the function and operation of a fuel flow divider can provide valuable insights into how aircraft engines maintain power and performance under various conditions.

The fuel flow divider works by regulating and distributing fuel from the engine’s fuel pump to the individual cylinders, ensuring uniform fuel delivery. This mechanism helps to prevent issues such as fuel starvation or uneven engine performance that can arise from inconsistent fuel flow. By dividing and supplying the fuel effectively, the fuel flow divider enables pilots and engineers to optimize engine operation, enhance fuel efficiency, and reduce the risk of engine failure during flight. In this article, we will delve deeper into the structure and functionality of the fuel flow divider, its significance in aviation, and the technological advancements that have streamlined its operation in modern aircraft engines.

What is a Fuel Flow Divider?

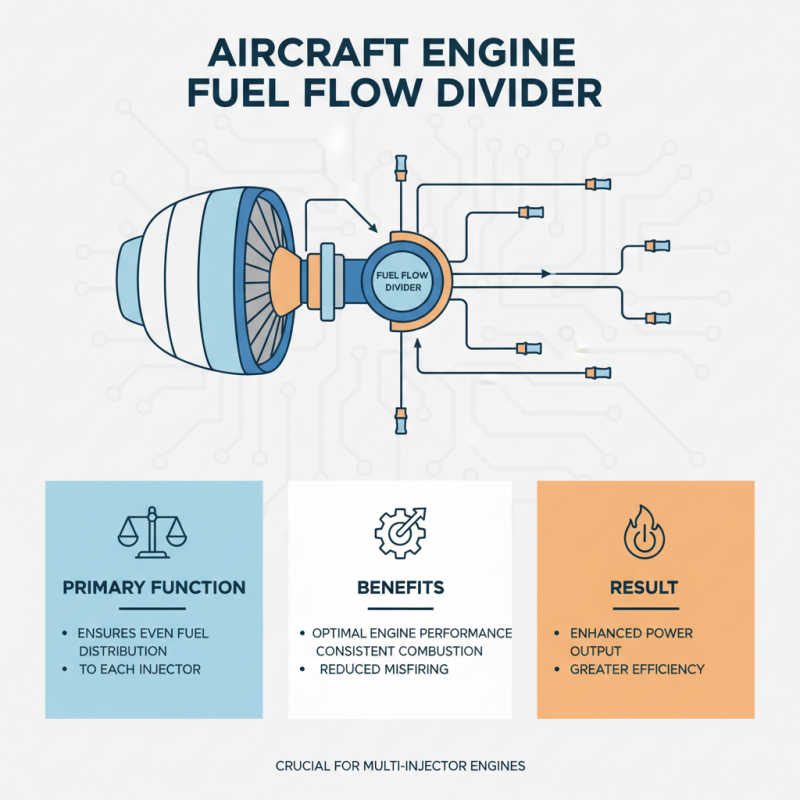

A fuel flow divider is a crucial component in aircraft engines, particularly in fuel injection systems. Its primary function is to evenly distribute fuel across multiple fuel injectors, ensuring that each cylinder receives the appropriate amount of fuel for optimal combustion. By doing so, the fuel flow divider helps maintain engine efficiency, reduces emissions, and enhances overall performance. This component is particularly important in multi-cylinder engines, where precise fuel management is essential for engine balance and power output.

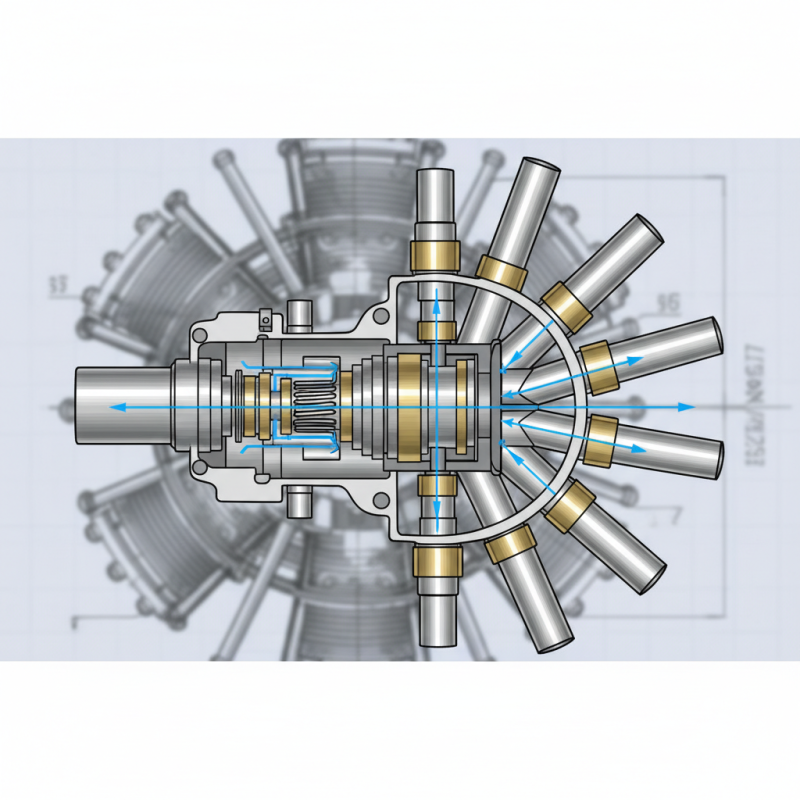

The operation of a fuel flow divider is relatively straightforward. Fuel from the fuel system enters the divider, which uses hydraulic principles to separate and direct the flow to each injector based on demand. Any discrepancies in fuel flow are corrected by the divider, allowing for adjustments that cater to varying engine conditions, such as changes in throttle position or air density. By maintaining consistent fuel delivery, the fuel flow divider plays a vital role in the functionality and reliability of aircraft engines, contributing to safer and more efficient flying.

The Role of Fuel Flow Dividers in Aircraft Engines

Fuel flow dividers play a crucial role in the operation of aircraft engines, particularly in those utilizing multiple fuel injectors. Their primary function is to ensure an even distribution of fuel to each injector, which is essential for optimal engine performance and efficiency. By balancing the fuel flow, the dividers help to maintain consistent combustion across all cylinders, reducing the risk of engine misfiring and enhancing overall power output.

In essence, the fuel flow divider operates by receiving fuel from the engine’s fuel pump and then partitioning it into separate streams that lead to each injector. This process is vital, especially in multi-engine aircraft where precise fuel management is necessary for safety and performance. Variations in fuel flow can lead to uneven engine performance, increased emissions, and potential engine damage. Therefore, the fuel flow divider is a key component in ensuring that the engine runs smoothly, reliably, and efficiently under various operating conditions, contributing significantly to the overall functionality of aircraft engines.

How Fuel Flow Dividers Distribute Fuel to the Injectors

A fuel flow divider plays a crucial role in aircraft engines by ensuring the even distribution of fuel to each injector. In a typical aircraft fuel system, the fuel is drawn from the tanks, filtered, and then delivered to the fuel flow divider. This component is designed with precision to manage the flow from a central fuel source to multiple injection points, maintaining the right balance that is vital for optimal engine performance.

As the fuel enters the flow divider, it is divided into smaller streams according to the specific requirements of each injector. The design of the flow divider incorporates calibrated orifices and pressure sensing mechanisms that adjust the quantity of fuel being delivered based on engine demands and operating conditions. This dynamic distribution ensures that all cylinders receive the appropriate amount of fuel for combustion, thereby enhancing engine efficiency and power output. By maintaining even fuel flow, the fuel flow divider also helps to prevent problems such as engine roughness or misfiring, which can arise from uneven fuel distribution.

The Mechanism of Operation of Fuel Flow Dividers

Fuel flow dividers are critical components in aircraft engines, primarily found in fuel injection systems. Their primary function is to distribute fuel evenly to multiple engine cylinders, ensuring optimal combustion and engine performance. By maintaining precise fuel flow rates, these devices help achieve better fuel efficiency and lower emissions. According to the Aircraft Engine Manufacturers Association, maintaining the right fuel-air mixture is essential for enhancing an engine's power output while minimizing fuel consumption.

The mechanism of operation of fuel flow dividers relies on internal pressure differentials. Typically constructed from lightweight materials, a flow divider adjusts fuel distribution based on engine demands and operational conditions. As fuel enters the divider, it encounters calibrated orifices that regulate flow rates to each cylinder, adapting to changes in engine load or throttle position. Advanced designs may include electronic controls to monitor and adjust flow in real-time, ensuring optimal performance across various flight regimes.

Tips: When inspecting fuel flow dividers, always look for signs of wear or clogging, as these issues can significantly affect engine efficiency. Regular maintenance checks, according to the manufacturer’s recommendations, can prevent fuel delivery problems. Additionally, consider upgrading to electronic fuel flow dividers for improved accuracy and responsiveness in fuel management.

Maintenance and Troubleshooting for Fuel Flow Dividers

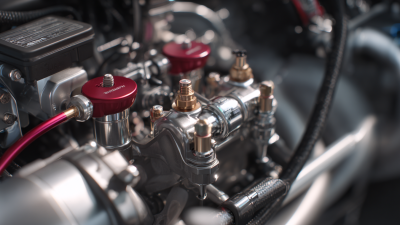

The fuel flow divider is a crucial component in aircraft engines, responsible for distributing fuel evenly to multiple fuel injectors. To ensure optimal performance, regular maintenance and troubleshooting of the fuel flow divider are essential. This involves inspecting the unit for signs of wear or damage, checking for blockages in fuel lines, and ensuring that all connections are secure. Neglecting this critical component can lead to uneven fuel distribution, engine performance issues, or even potential safety hazards.

When maintaining a fuel flow divider, here are a few tips to keep in mind: First, always refer to the manufacturer's maintenance manual for specific guidelines on inspection intervals and maintenance procedures. Second, use clean, high-quality fuel to minimize the risk of contaminants that can clog the system. Finally, consider implementing a regular testing schedule to monitor the fuel flow rates and ensure that the divider is functioning as intended, allowing for timely troubleshooting when discrepancies arise.

In troubleshooting, watch for symptoms such as engine roughness or decreased performance, which can indicate issues with the fuel flow divider. Addressing any detected problems early can save time and resources, enhancing the overall reliability of the aircraft's fuel system.

Related Posts

-

10 Essential Tips for Understanding Aircraft Systems Effectively

-

Why Understanding Aviation Fuel Systems is Crucial for Efficient Flight Operations

-

Exploring the Future of Aviation: How Kit Aircraft are Redefining DIY Flight for Enthusiasts

-

Unlocking the Future of Energy: How Consolidated Fuel is Revolutionizing the Fuel Industry

-

5 Best Solutions for Exceptional Aircraft Service Efficiency

-

Revolutionizing Aviation: The Future of Fuel Injection Systems in Aircraft Design