10 Essential Tips for Understanding Aviation Fuel Systems

Understanding aviation fuel systems is crucial for safe and efficient flight operations. According to Dr. Emily Carter, an expert in aerospace engineering, "Aviation fuel systems are the lifelines of an aircraft." Her insight emphasizes the importance of these systems in maintaining aircraft performance.

These systems are complex and require careful management. They ensure that the fuel supply is consistent and reliable. However, many overlook the intricacies involved. Issues like fuel contamination can lead to serious problems. Pilots and engineers must familiarize themselves with potential pitfalls.

Moreover, regular inspections are essential for safety. Fuel system failures can happen unexpectedly. Learning the differences between various fuels is also vital. Each type has specific properties that can affect performance. Understanding aviation fuel systems requires attention to detail and continuous learning.

Key Components of Aviation Fuel Systems

Aviation fuel systems are critical for aircraft performance and safety. These systems consist of several key components, each playing a unique role. Fuel tanks store aviation fuel. They are built to withstand environmental pressures and maintain the integrity of the fuel. Consider that over 40% of aircraft operational issues stem from fuel system failures, as per industry reports. This statistic underscores the essential need for proper tank design and regular maintenance.

Fuel pumps are another important aspect. They ensure that fuel reaches the engines at the right pressure and flow rate. Any malfunction here could lead to inadequate fuel delivery. In fact, studies indicate that nearly 25% of maintenance issues relate to pump failures. This highlights the importance of selecting quality components and conducting routine inspections.

Fuel filters are also vital. They prevent contaminants from entering the fuel flow, ensuring clean fuel reaches the engines. Data shows that around 15% of engine malfunctions are due to dirty fuel systems. The aviation industry often overlooks the significance of clean fuel. Proper filtration systems can make a significant difference. Regular updates to maintenance protocols can address these concerns proactively.

10 Essential Tips for Understanding Aviation Fuel Systems - Key Components of Aviation Fuel Systems

| Component | Function | Common Issues | Maintenance Tips |

|---|---|---|---|

| Fuel Tank | Holds the aviation fuel | Leakage, corrosion | Regular inspections, check seals |

| Fuel Pump | Transfers fuel from tanks to engines | Failure to pump, pressure issues | Test pressure regularly, replace as needed |

| Fuel Filter | Cleans fuel before it reaches the engine | Clogging, contamination | Change filters at regular intervals |

| Fuel Injector | Delivers fuel into the combustion chamber | Blockage, uneven fuel delivery | Clean or replace regularly |

| Fuel Gauging System | Measures the amount of fuel in the tank | Inaccurate readings | Calibrate system periodically |

| Vent System | Prevents vacuum formation in tank | Blockages, pressure imbalances | Inspect vents regularly |

| Fuel Control Unit | Regulates fuel flow to the engine | Malfunction, incorrect flow | Test functionality as part of routine checks |

| Fuel Additives | Enhances fuel properties | Over-addition can harm fuel system | Follow manufacturer recommendations |

| Return Lines | Directs unused fuel back to the tank | Leaks, blockages | Inspect for leaks and clogs |

| Emergency Shutoff | Turns off fuel flow in emergencies | Ineffective in emergencies | Test functionality during checks |

Types of Aviation Fuels and Their Properties

Aviation fuels are critical for the efficiency and safety of aircraft operations. Two primary types are Jet A and Jet A-1. Jet A is commonly used in the United States, while Jet A-1 has a lower freezing point. This makes it suitable for international flights and colder climates. Suppliers must meet strict standards to ensure fuel quality. According to a 2022 FAA report, 3.5 billion gallons of Jet A fuel were consumed in the U.S. alone.

Understanding fuel properties is essential. The calorific value of Jet A-1, for instance, is about 43 MJ/kg. This energy content affects engine performance and range. It’s crucial to remember that not all fuels have the same specifications. Variants may possess different additives and properties. This can impact combustion efficiency and emissions, introducing variability in operational costs.

Tip: Always check the fuel quality. Contaminated fuel can cause severe engine issues. Also, monitor fuel density; it can change with temperature. Fuels with lower density provide less energy.

One interesting fact is that biofuels are becoming more prevalent. They offer lower carbon emissions but may not meet all performance requirements. Some airlines are experimenting with blends. These fuels can sometimes behave unpredictably. As the industry evolves, realizing these nuances becomes vital. Awareness of fuel types and their implications can enhance operational decisions in aviation.

Types of Aviation Fuels and Their Properties

Fuel System Design and Layout in Aircraft

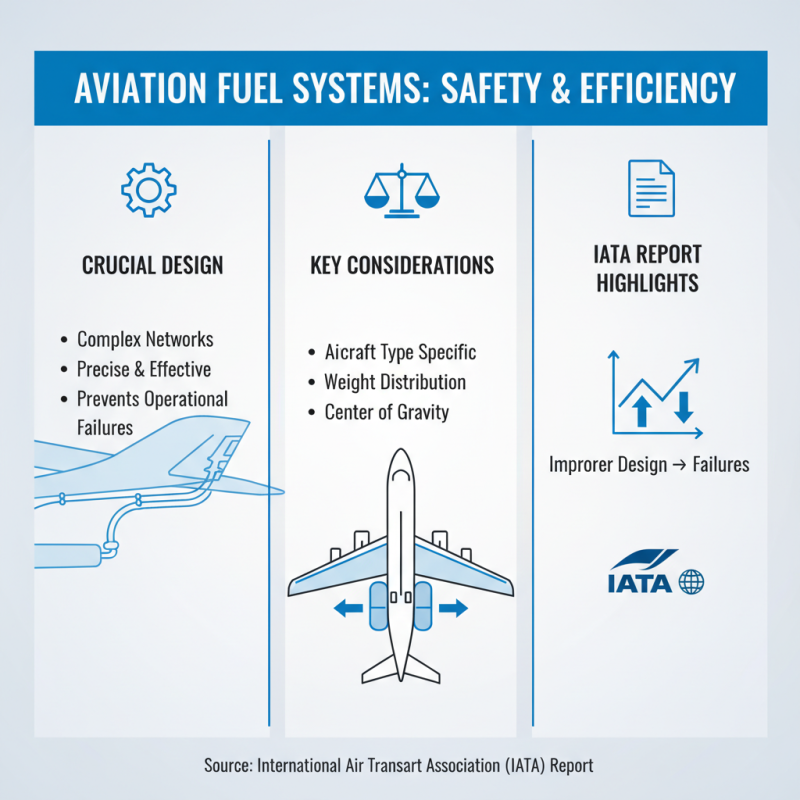

Understanding the design and layout of aviation fuel systems is crucial for safety and efficiency. Fuel systems are complex networks. They must be precise and effective. According to a report by the International Air Transport Association (IATA), improper fuel system design can lead to significant operational failures. Each aircraft type has unique requirements. The weight distribution and center of gravity impact fuel tank placement.

Fuel system layout often involves multiple tank configurations. Some planes may have wing-mounted tanks, while others use fuselage tanks. Research shows that more than 70% of jet fuel is stored in wings. This distribution helps with weight balance during flight. However, these designs need frequent maintenance checks. Failures can occur due to old materials or poor installation practices.

Inconsistent fuel flow can result in performance issues. Data suggests that nearly 15% of commercial aircraft face fuel starvation problems. Operators must regularly analyze fuel system performance and conduct thorough inspections. Being proactive is key. The aviation community often overlooks the importance of routine checks. Ignoring these systems could have critical consequences, leading to safety risks.

Maintenance Best Practices for Fuel Systems

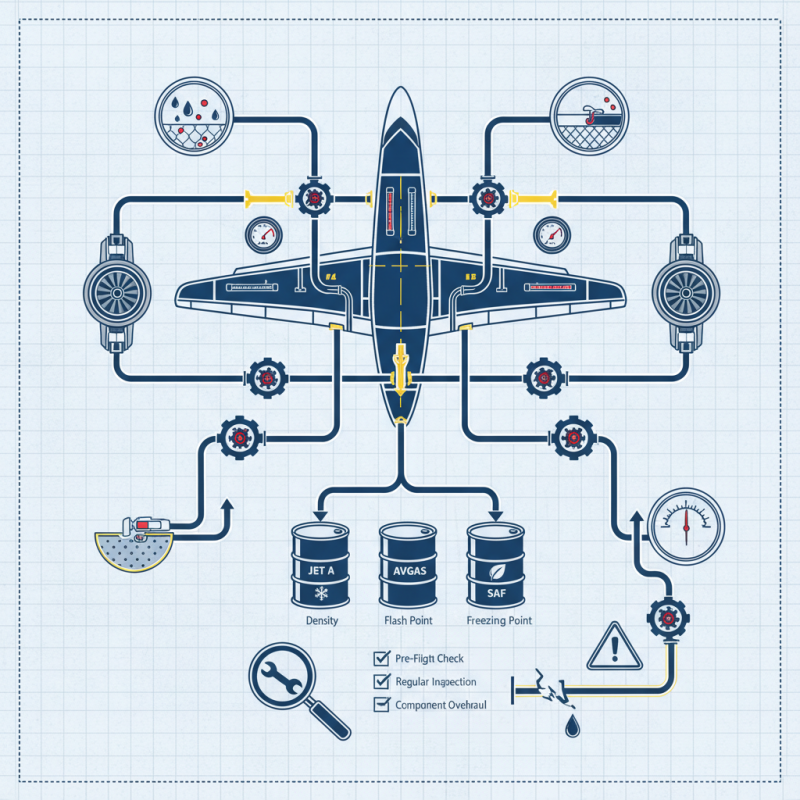

Aviation fuel systems require regular maintenance to ensure safety and efficiency. Conducting routine inspections is essential. Look for signs of leaks or corrosion. Check the fuel filters and strainers often. They can get clogged with dirt or debris. Neglecting these components can lead to system failures.

Testing fuel quality is crucial. Contaminated fuel can damage engines. Use proper sampling techniques to analyze fuel integrity. Remember that even small amounts of water can cause significant issues. It's important to store fuel in clean, sealed containers to prevent contamination.

Training staff on best practices is vital. They should understand the procedures for handling and fueling aircraft properly. Mistakes can happen, and poor communication can lead to accidents. Regular maintenance checks should be documented. This ensures accountability and a record of the system's history. Always keep learning from past mistakes; improvement is key in aviation maintenance.

Understanding Fuel Flow and Delivery Mechanisms

Understanding fuel flow and delivery mechanisms is crucial in aviation. Fuel systems are intricate yet vital components of an aircraft. They ensure that engines receive the right amount of fuel at the right time. According to a report from the International Air Transport Association (IATA), around 26% of airline operating costs stem from fuel expenses. Therefore, an efficient fuel system can significantly impact profitability.

The delivery mechanism typically involves several key components: fuel tanks, pumps, filters, and control valves. Fuel flows from the tanks through a series of pumps. These pumps keep the fuel under pressure, preventing vapor formation. Filters remove impurities, ensuring that only clean fuel reaches the engines. However, issues can arise. If filters clog, it can lead to engine performance problems or, in severe cases, engine failure. Last year, an aviation safety report highlighted that 18% of engine incidents were linked to fuel flow disruptions.

However, the understanding of these systems is not without its challenges. Maintenance teams must be vigilant. Aging fuel systems may not operate as efficiently as intended. Additionally, regulatory standards can sometimes lag behind technological advancements. This delay can create gaps in safety and reliability. Aviation stakeholders must continuously analyze and adapt their understanding of fuel flow and delivery mechanisms.

Related Posts

-

2025 Top Aviation Fuel Systems Innovations for Optimal Efficiency

-

What is Fuel System Aviation and How Does It Impact Flight Safety

-

2026 Best Aviation Fuel Systems How Do They Work?

-

How to Optimize Fuel Injection in Aviation for Improved Performance and Efficiency

-

Building Your Dreams: A Comprehensive Guide to DIY Kit Aircraft for Aviation Enthusiasts

-

How to Get Started in Experimental Aviation: A Beginner's Guide