Top 5 Best Experimental Aircraft Parts for Optimal Performance?

The world of aviation is constantly evolving, and experimental aircraft parts play a crucial role in that innovation. As noted by Dr. Emily Carter, an aerospace engineering expert, "The right aircraft components can define performance and safety standards." This highlights the importance of selecting optimal parts for experimental aircraft.

When building or modifying an aircraft, the choice of components significantly impacts its performance. For example, lightweight materials improve fuel efficiency, while advanced avionics enhance navigation and safety. Many enthusiasts and professionals overlook how small changes can lead to remarkable enhancements. However, not all experimental parts are created equal. It is essential to conduct thorough research and testing before making decisions.

Remarkably, the balance between performance and safety is not always clear-cut. Some aircraft builders may prioritize speed over reliability, only to face consequences later. It begs the question: are we sacrificing safety for performance? Therefore, understanding which experimental aircraft parts truly offer advantages is vital for any aviation aficionado.

Essential Materials Used in Experimental Aircraft Parts

When building experimental aircraft, the choice of materials is crucial for performance and safety. Lightweight alloys, such as aluminum and titanium, dominate the industry. These metals provide strength without excessive weight. Many builders also consider carbon fiber composites for structural parts. They offer excellent stiffness and durability, but handling them requires care and skill.

Wood remains a popular option for certain designs. It is easy to work with but can be heavy. Plywood is often used for ribs and bulkheads. The challenge lies in ensuring it is treated properly to resist moisture and decay. Additionally, using high-quality adhesives is essential when working with wood.

Another interesting material is fiberglass. It can be molded into various shapes, providing flexibility in design. However, the process can be messy and requires proper ventilation. Builders sometimes overlook the importance of finishing techniques. A well-finished surface can enhance both performance and aesthetic appeal. Each material has its strengths and weaknesses, and careful consideration can lead to innovation in the field.

Top 5 Best Experimental Aircraft Parts for Optimal Performance

Key Components Impacting Aerodynamic Efficiency in Experimental Designs

When designing experimental aircraft, key components significantly impact aerodynamic efficiency. The wings are often a focal point. Their shape and material can alter airflow dramatically. A well-designed wing reduces drag and enhances lift. Consider the world of winglets. These attachments at the wing tips can reduce vortex drag. Yet, not every design works for all aircraft.

Control surfaces, like ailerons and elevators, also matter. They dictate how the aircraft maneuvers in the air. The balance and responsiveness influence performance. A poorly calibrated control surface could lead to instability. Experimentation is crucial, but it's not without risks. Many builders face the challenge of finding the optimal pitch and roll rates.

Another important factor is the landing gear. It affects weight distribution and drag. A heavy or poorly designed landing gear may slow the aircraft during takeoff and landing. The choice of materials plays a role too. Composite materials can lighten the load but may require a learning curve in handling. Each decision impacts the overall performance of the aircraft. It's a puzzle that demands attention to detail and a willingness to adapt.

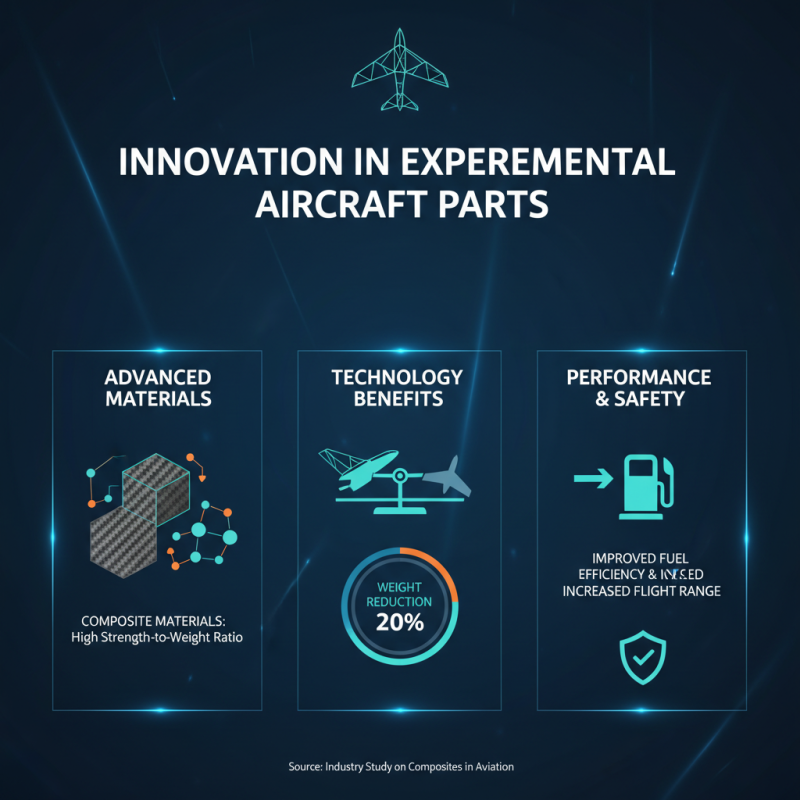

Innovative Technology Driving Performance in Experimental Aircraft Parts

Innovation is transforming the world of experimental aircraft parts. Advanced materials and technologies are crucial for enhancing performance and safety. For instance, composite materials have gained traction as they offer high strength-to-weight ratios. A study shows that using composites can reduce aircraft weight by up to 20%. This reduction improves fuel efficiency and increases flight range.

Another area where technology excels is in avionics systems. Modern glass cockpit displays provide real-time data, enhancing pilot situational awareness. Integrated sensors and automation allow for smoother operations. Reports indicate that effective data visualization can cut down decision-making time by 30%. This can be life-saving in critical situations.

**Tip:** Always keep up with the latest technological advancements. Reading industry publications can provide insights into new materials and components.

Despite all these advancements, challenges persist. The complexity of integrating new technologies can lead to unforeseen issues during flight tests. This might require multiple revisions and adjustments, slowing down development. A balanced approach to innovation and thorough testing is vital for success.

**Tip:** Document every change rigorously. Tracking modifications helps identify what works and what doesn’t over time.

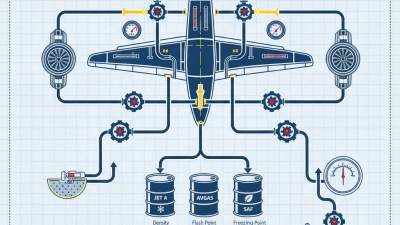

Maintenance Considerations for Enhanced Longevity of Aircraft Components

Maintaining aircraft components is crucial for ensuring safety and performance. Regular inspections can detect signs of wear. According to a recent industry report, 30% of accidents stem from mechanical failures. This highlights the importance of vigilant maintenance practices.

Routine checks help identify issues before they become significant problems. Greasing pivot points and checking hydraulic fluids should be standard. The American Institute of Aeronautics states that proper maintenance can enhance component lifespan by up to 50%. Ignoring small issues often leads to costly repairs down the road.

Utilizing high-quality materials in components is key. However, using subpar parts can cause unexpected failures. Recent studies suggest that nearly 20% of component malfunctions are linked to poor-quality materials. Being proactive about part selection and maintenance fosters better aircraft performance, even if it requires additional effort. Regular training for maintenance crews is also vital. Accurate knowledge on best practices contributes greatly to longevity.

Top 5 Best Experimental Aircraft Parts for Optimal Performance

| Part Name | Material | Weight (lbs) | Cost ($) | Maintenance Frequency (hours) |

|---|---|---|---|---|

| Wing Spar | Aluminum Alloy | 20 | 1200 | 100 |

| Control Surfaces | Composite Material | 15 | 800 | 150 |

| Engine Mount | Steel | 25 | 700 | 200 |

| Landing Gear | Titanium | 30 | 1500 | 250 |

| Fuel Tank | Aluminum | 18 | 400 | 300 |

Safety Standards and Regulations for Experimental Aircraft Parts Usage

Safety in experimental aircraft is paramount. Regulations, like those from the FAA, dictate specific standards for parts. For example, all components must undergo rigorous testing. Reports indicate that nearly 40% of accidents stem from equipment failures. This highlights the need for reliable parts.

Materials used in these aircraft must meet certain criteria. They should withstand high stress and extreme conditions. A study found that corrosion-resistant metals are crucial. Many builders often overlook this requirement. Regular inspections can help identify potential weaknesses in parts. This practice is essential for maintaining safety.

Moreover, documentation is vital when using experimental parts. Pilots must have clear records of all inspections and modifications. A survey showed that 55% of pilots felt uninformed about safety protocols. Therefore, builders and pilots must prioritize education and adherence to regulations. A collaborative effort can enhance safety.

Related Posts

-

Top 10 Essential Aircraft Systems Every Pilot Should Understand

-

Top 10 Fuel System Aviation Innovations You Need to Know About

-

Understanding the Evolution of Aircraft Service: From Maintenance to Passenger Experience

-

Top Kit Aircraft for Enthusiasts and Builders in 2026?

-

Revolutionizing Aviation with Advanced Fuel Injection Systems Enhancing Efficiency and Performance

-

10 Essential Tips for Understanding Aviation Fuel Systems