2026 Best Experimental Aircraft Innovations and Trends to Watch?

The world of experimental aircraft is rapidly evolving. Innovations in design and technology are transforming the aviation landscape. From electric propulsion to advanced materials, trends are reshaping how we think about flight.

Experimental aircraft are at the forefront of these changes. They push boundaries and challenge existing norms. New trends emphasize sustainability and performance. Exciting developments in autonomous flight also capture attention. Emerging technologies promise to enhance safety and efficiency.

However, the future is not without challenges. The integration of new systems can lead to unforeseen issues. Developers must carefully consider regulatory paths. Balancing innovation with safety is crucial. The journey ahead is filled with potential and obstacles alike. The evolution of experimental aircraft will certainly be a topic to watch in 2026.

Innovative Materials Transforming Experimental Aircraft Design in 2026

The landscape of experimental aircraft design in 2026 is poised for transformation, largely due to innovative materials. Advanced composite materials, including carbon fiber and bio-derived polymers, are gaining traction. According to a recent industry report, 45% of new experimental aircraft are expected to utilize these lightweight materials, enhancing performance significantly. The reduced weight allows for improved fuel efficiency, which is a top concern for many designers.

However, the journey is not without challenges. The integration of new materials can complicate manufacturing processes. Fabricators are often faced with increased costs and longer production times. Inconsistent quality of raw materials can lead to structural issues, necessitating further testing and assessment. A significant 30% of projects in development have reportedly hit roadblocks due to these factors.

Moreover, the environmental impact of material sourcing can't be overlooked. While bio-based materials promise sustainability, their supply chains can be unstable. It’s crucial for the industry to evaluate the lifecycle impacts of these innovations. As designers strive for breakthroughs, they must balance performance advantages with sustainability concerns and production viability. This intricate relationship between innovation and practicality will shape the future of experimental aircraft design in the coming years.

2026 Best Experimental Aircraft Innovations and Trends to Watch

| Innovation | Description | Material Type | Impact on Design | Potential Benefits |

|---|---|---|---|---|

| Advanced Composite Materials | Utilization of lightweight carbon fiber and aramid fibers for enhanced structural integrity. | Composites | Reduces weight, increases efficiency and performance. | Improved fuel efficiency and range. |

| 3D Printing Technology | Additive manufacturing for rapid prototyping and part production. | Metals, Plastics | Facilitates complex geometries not possible with traditional methods. | Cost-effective production and reduced lead times. |

| Smart Materials | Materials that can adapt to environmental changes, improving performance. | Shape-memory alloys, piezoelectric materials | Enables self-regulation and dynamic responses in aircraft systems. | Enhanced control and safety under varying flight conditions. |

| Sustainable Fuel Technologies | Development of biofuels and synthetic fuels to reduce carbon footprint. | Biofuels | Reduces dependency on fossil fuels and lowers emissions. | Promotes environmental sustainability and regulatory compliance. |

Advancements in Aerodynamics Shaping the Future of Experimental Flight

Advancements in aerodynamics are profoundly shaping experimental flight.

New designs focus on efficiency and speed.

Smooth surfaces reduce drag, allowing for faster travel.

Innovative wings are being developed to enhance lift and maneuverability. These concepts push the boundaries of what we know about flight.

However, the journey isn’t without challenges. Some experimental designs face issues with stability.

Engineers are continuously refining concepts based on flight data.

Sometimes, unexpected results lead to reevaluation of existing theories.

This trial-and-error process is crucial in innovation.

Balancing performance and safety remains a priority for researchers.

Moreover, emerging technologies are changing our understanding of airflow around aircraft.

Computational fluid dynamics (CFD) plays a key role in predicting performance.

Yet, simulations can't always replicate real-world behavior.

Experimentation in actual flight conditions is essential.

This blending of computational and experimental methods is where true advancements occur.

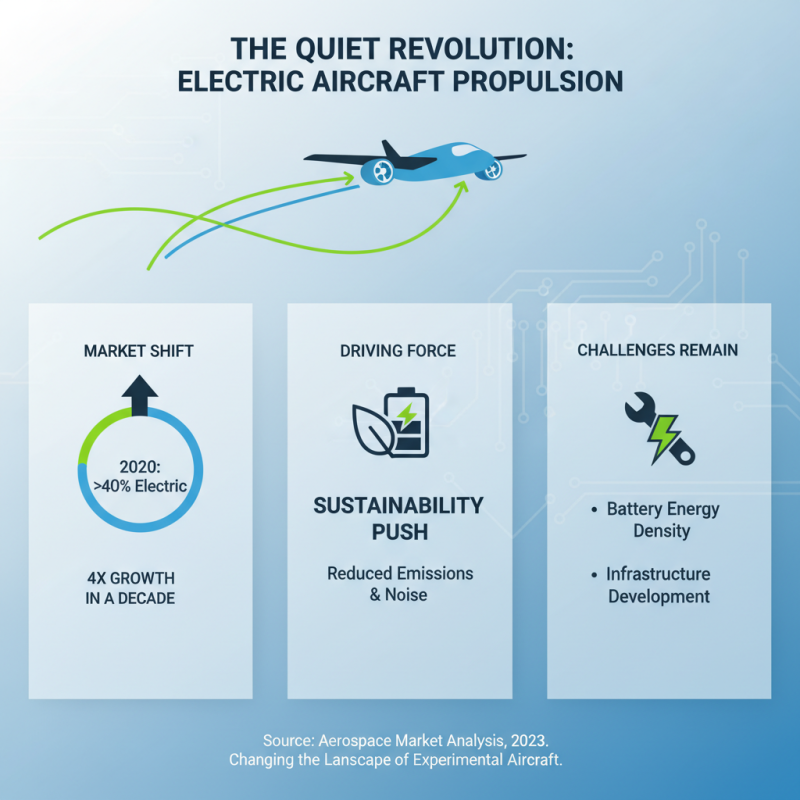

Emerging Technologies in Electric Propulsion for Experimental Aircraft

Electric propulsion is changing the landscape of experimental aircraft. Recent data indicates that more than 40% of the aerospace market will shift to electric systems by 2030. This represents significant growth compared to only 10% in 2020. The move towards sustainability is motivating this rapid transition. However, challenges remain.

Battery technology plays a crucial role in this evolution. Current battery systems struggle with energy density. They simply do not provide enough power for long flights. As a result, researchers are exploring advanced lithium-sulfur options. These could potentially double the energy capacity. However, practical implementation is still years away. It shows a gap between theory and application.

Moreover, hybrid propulsion systems are gaining traction. They combine traditional engines with electric motors. This could ease pilots into new technologies. Yet, optimizing efficiency is complex. Studies show that only 30% of current hybrid designs meet performance expectations. More innovation is necessary to close this performance gap. The next few years will be critical for these innovations to mature and become viable.

Trends in Flight Control Systems Enhancing Aircraft Performance

Recent advancements in flight control systems are set to redefine the future of experimental aircraft. In a recent industry report, it was noted that over 70% of new aircraft innovations focus on enhancing control systems. These systems use advanced algorithms to improve stability and maneuverability. With improved sensors and real-time data processing, pilots can receive immediate feedback during flight. This responsiveness is crucial for experimental aircraft, where every second counts.

Moreover, automation in flight control has seen significant growth. Research indicates that automated systems can reduce pilot workload by up to 50%. This allows pilots to focus on strategic decision-making, rather than solely on manual controls. However, reliance on automation raises questions about pilot training and competency. Ensuring pilots maintain essential skills remains a key concern. Some critics argue that this reliance could lead to over-dependence on technology.

Another trend involves the integration of artificial intelligence in flight control. AI can analyze vast amounts of data quickly, optimizing performance in real-time. Nevertheless, incorporating AI brings its own challenges. Data security and system reliability must be prioritized. The aviation community continues to explore these innovations while addressing the potential risks and limitations they pose.

2026 Best Experimental Aircraft Innovations in Flight Control Systems

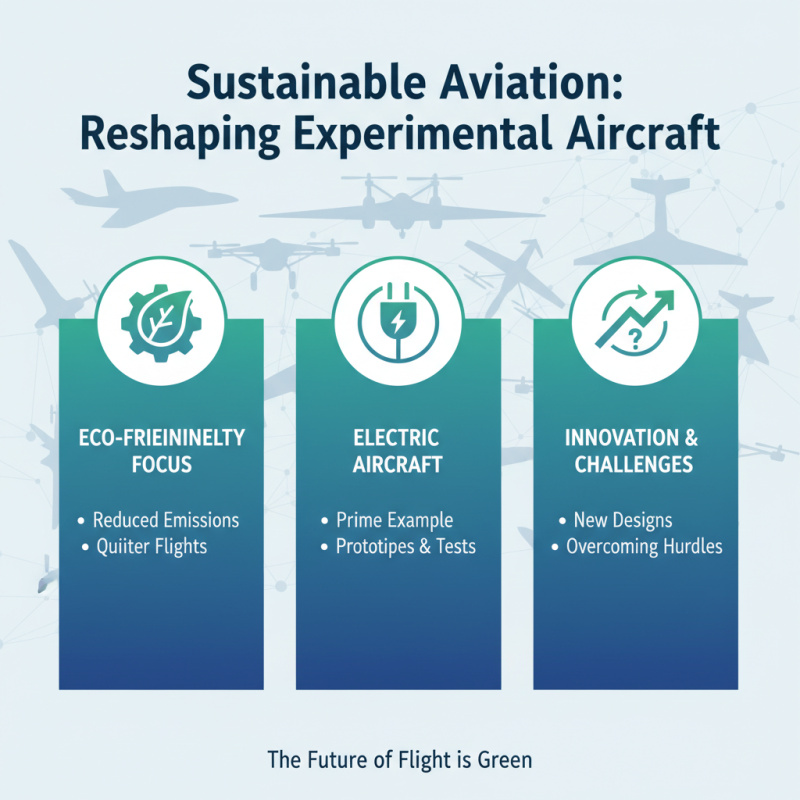

Impact of Sustainable Aviation Practices on Experimental Aircraft Development

The sustainable aviation movement is reshaping experimental aircraft development. With a growing focus on eco-friendliness, innovations are emerging. Electrically powered aircraft are a prime example. They promise reduced emissions and quieter flights. These designs are not just theoretical. Prototypes and tests are becoming more common. Yet, challenges remain.

Battery technology is crucial. Current batteries are heavy and limit range. Finding lighter solutions is essential for progress. Engineers are exploring alternative fuels too. Sustainable aviation fuels (SAFs) offer potential, but scaling production presents hurdles. The reliance on conventional materials in construction is still prevalent. Many designs lack full sustainability in their lifecycle.

Collaborative efforts are vital in addressing these issues. Universities, researchers, and startups are at the forefront. They often face obstacles due to funding and resource accessibility. The path to innovation is filled with setbacks. Testing ideas in real-world scenarios brings mixed results. While failures offer valuable lessons, they also highlight the unpredictable nature of development in this field.

Related Posts

-

Building Your Dreams: A Comprehensive Guide to DIY Kit Aircraft for Aviation Enthusiasts

-

Exploring the Future of Fuel Injection Aircraft: Innovations and Advancements in Aviation Technology

-

Top 10 Fuel System Aviation Innovations You Need to Know About

-

How to Optimize Fuel Injection in Aviation for Improved Performance and Efficiency

-

10 Best Experimental Aviation Innovations You Should Know?

-

10 Best Fuel Injection Systems in Aircraft: A Comprehensive Guide